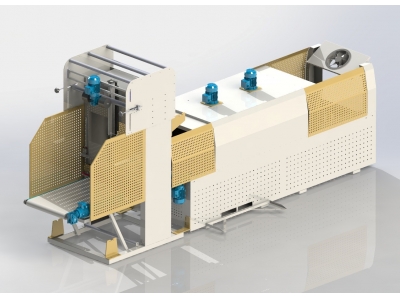

Fully Automatic Shrink

Automatic Shrink Machine; It is the model used to shrink the product in a faster and faster way by reducing the work force. It carries out the shrinking process in a serial manner by covering the products conveyed to the pre-feeding band with packaging without touching. It usually covers a large part of the product by stretching it with PE packaging so that the boxes are not damaged during transportation. It is also used to combine boxes into multiple groups to form a single whole. It meets the demands of a wide range of customers in various sectors such as food, beverage, pharmaceutical, chemical, cosmetics, paint, printing and automotive. It provides easy and safe packaging of products with or without pan. In this way, it both visualizes the products and reduces the cost of the parcel.

- Operator Control System: 7” Touch PLC Screen

- P.I.D. Bonding is provided by Electronic Temperature Control System.

- Capacity: 8-12 Packs / Min. (According to product size)

- Film drive mechanism with lower and upper motors

- Adjustable tunnel conveyor speed

- All electrical cables inside the tunnel are non-combustible external shielded cables.

- Required air pressure: 5 - 6 bar

- Electricity: 380 V. 50-60 Hz. 1 Ph

- The machine is installed on site by our assembly team, given working training and delivered with usage and maintenance instructions.

- Machines - 2 YEARS - guaranteed.

- Production from static painted or completely chromed stainless steel

- Front feeding or side feeding grouping system depending on the coupling method to the production line

- Jaw length from 60 cm to 120 cm and tunnel size option according to the largest product; According to the dimensions of the products you will work with, the standard manufacturing dimensions of the machine are changed and a healthier operation is ensured.

- Soft pressure piston to fix the product during the cut-paste process

- Intra-tunnel transport system (silicone coated shafts, wire mesh tape, teflon mesh tape or heat resistant plastic modular tape)

- Side ironing rollers at the tunnel exit

English

English Türkçe

Türkçe English

English Français

Français Русский

Русский العربية

العربية