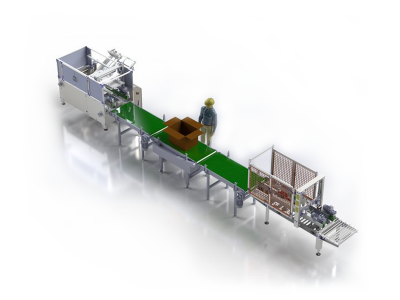

Single Personnel Box Filling Line

Single Personnel Box Filling Line; For the packing process of your products, empty parcels are prepared with the Fully Automatic Box Preparation Machine and removed to the filling conveyor. After packing your products, it is closed and taped with a Fully Automatic Box Sealing and Banding Machine to complete your production. The machines make it easy to fill your ready-to-carry products by constantly preparing empty boxes, and they also reduce your production cost by providing automatic closing works.

- Operator control system: 7” Touch PLC Screen

- Capacity: 12-15 parcels / min. (According to box size)

- Magazine capacity of empty boxes: 120-150 boxes

- It adapts to your parcels of different sizes thanks to its mechanism with 6 adjustment levers.

- Package tape mechanism: 4-6 cm wide duct tape can be attached.

- Door and safety switch sensors for occupational safety in machines

- Machine warns in case of box and tape decrease.

- Required air pressure: 5 - 6 bar

- Electricity: 380 V. 50-60 Hz. 1 Ph.

- The machine is installed on site by our assembly team, given working training and delivered with usage and maintenance instructions.

- Machines - 2 YEARS - guaranteed.

- For the filling conveyor; Idler Roller Belt or Motorized Conveyor Belt

- Production from static painted or completely chromed stainless steel

- Box Sealing System: Hot Melt system

- Large, standard and small machine options; The standard manufacturing dimensions of the machine can also be changed according to the dimensions of the boxes you will work with, and a more harmonious operation is provided for the products.

- Automatic box size adjustment system; With servo motors and recipe registration system, automatic and fast transition to different size box settings is provided with a single click.

- Mixed parcel making feature; It provides fast positioning according to the dimensions of the box, thanks to special sensors and servo motors, according to mixed boxes of different sizes.

English

English Türkçe

Türkçe English

English Français

Français Русский

Русский العربية

العربية